Topeka Plug & Play: Cohort Participants

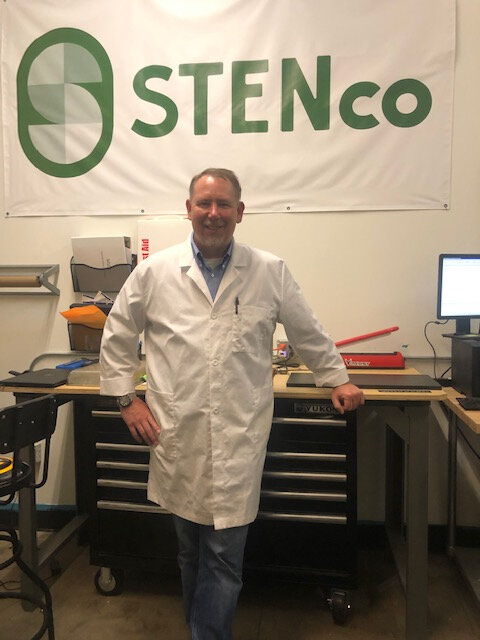

STENCo: March 2021 Cohort

A career chemist, John Brown has always enjoyed tinkering. Growing up in Selma, Alabama, the amateur photographer developed his own film and negatives. In college, he studied chemistry, physics and anthropology and worked in an artifact preservation lab.

Following a career developing drug delivery systems and working with biodegradable polymers for the pharmaceutical industry, Brown worked with a biodiesel technology company that designed two plants in China.

In 2019, he left the company and moved to Birmingham, Alabama, where he’s founded STENCo, LLC, which stands for Save the Earth Now. Brown is focusing his expertise on creating biodegradable packaging for the food and beverage market that would be cost effective and home compostable. Eventually, Brown hopes to develop packaging that could accommodate products with a longer shelf life.

“When I started, it looked like I had a meth lab in my garage,” said Brown. “I didn’t leave my garage door open very often because I was afraid the neighbors would talk.”

He leveraged his contacts in the field and began getting encouraging results for his efforts to create a sustainable, economical biodegradable barrier product that potentially could replace 13 billion coffee pods, 150 billion straws and 500 billion cups.

“Single-use plastics are going through a societal revolution and a legislative revolution,” said Brown. “There isn’t a good alternative right now, so this is a massive opportunity.”

Brown said the STENCo material, comprising proteins, cellulose and polysaccharides, forms “a protective bubble” that can withstand environmental factors and then fully degrade when conditions are right. In addition to its biodegradable properties, the material is microwavable and grease and water resistant.

“Some things will be more compatible with our approach than others,” he said. “You won’t see a biodegradable Coke bottle any time soon.”

Brown said STENCo, which has five employees, is primarily working with consumer-facing organizations interested in shelf-ready solutions and their suppliers.

“The material already competes favorably with plastics, a surprising outcome we didn’t anticipate would happen in less than geological time,” said Brown, who filed his first patent in 2019. Later that year, he established the LLC, transferred patents to raise money for the venture and met with major players to discuss his plans.

“A few people who know me and my background were very supportive and believed in what I was doing from the start,” said Brown. “When we met with larger companies, they were more incredulous. Most were skeptical that a guy in his garage could come up with this concept when their R&D teams hadn’t. Fortunately, we’ve been able to share solid science behind our testing and have gained credibility.”

Brown participated in three previous Plug and Play opportunities before joining the Topeka cohort last fall.

“Hill’s Pet Nutrition and Cargill were already of interest to us because of their sustainability commitments, and we now have direct access to those companies to see if there’s a good fit for working together,” said Brown.

Brown said Plug and Play participation has resulted in initial investments that have enabled the company to outfit a lab and the team continues to capitalize on opportunities.

“The attention we’ve received for our biodegradable packaging effort has exceeded all of our expectations,” he said. “We’re not revenue positive yet, so we have to remain hungry, lean and aggressive. We spend every investment dollar like it’s our own. Fortunately, I’m notoriously cheap. We want to be good stewards with the people who’ve put } faith in us and reward them well when success comes.”

BOND PET FOODS: October 2020 Cohort

For 25 years, Rich Kelleman worked for the biggest advertising agencies in the world. In 2010, a position with Burger King brought him to Boulder, Colorado, to help the fast food company compete more effectively against fresh casual chains like Chipotle Mexican Grill and Panera.

“That experience really opened my eyes to the challenges of sourcing ingredients and coincided with

a personal interest in sustainable agriculture and farm animal welfare,” said Kelleman, founder and CEO of Bond Pet Foods.

A “voracious carnivore” before adopting a vegan diet, Kelleman became mindful of how meat is sourced and raised and his growing knowledge played a bigger role in his food choices and entrepreneurial aspirations.

Citing a 2017 UCLA white paper on the impact of meat production for pet consumption, Kelleman said, “One of the high-level conclusions was that cats and dogs are the fifth largest consumers of meat in the world, and the production of food and byproducts accounts for 20% to 30% of all greenhouse emissions.”

Kelleman is borrowing on biotech breakthroughs used to brew beer and make cheese to “crack the code” for pet protein now and potentially human food consumption later.

In August 2020, the company announced strides in creating an animal- free chicken protein expected to debut in the market in 2023.

“Commercially, it’s easier to replicate meat protein properties for pets because it’s not about the taste or the texture or the sizzle that humans require,” Kelleman said. “For pets, the end product needs to be nutritious but it doesn’t have to look like a steak or a pork chop.”

But it does have to taste good. His dog Rumples is the company’s taste tester and chief dog officer, “a sweet and adorable pit bull, Rottweiler and Shar Pei mix that will lick you face off,” said Kelleman. “We don’t carry something forward if she doesn’t like it.”

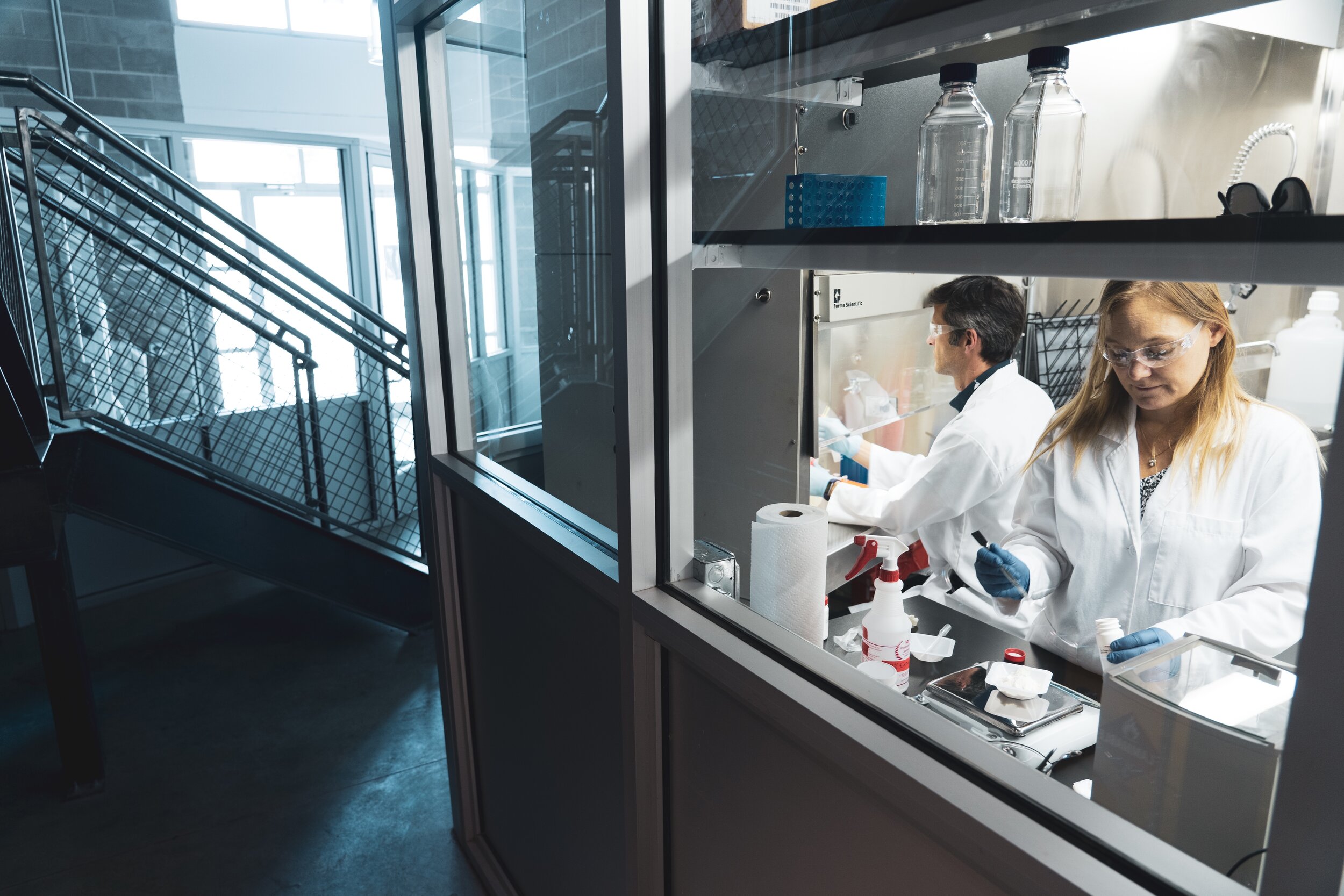

Kelleman spent a year outlining a potential process, recruiting a co-founder and building veterinary and biotech teams to look at new approaches, ultimately landing on microbial fermentation.

“We can brew the protein, gently dry and grind it into a fine powder, and then use the ingredient as a primary source of nutrition in a pet food product, be it extruded, freeze-dried, dehydrated or baked,” he said. “We’re using a microbial fermentation process that’s been around for 50 years to brew beer and generate enzymes that separate curds and whey in about 80% of cheese production.”

Kelleman’s team uses DNA from a chicken, couples it with yeast, ferments it with sugar, salt and minerals, and then grows the protein in a tank.

To help demystify the process, Kelleman and his science team drove to a heritage chicken farm in Lindsborg, Kansas, and selected Inga, a Heritage hen, to serve as the source of Bond Pet Foods’ cultured protein product.

“We could have downloaded the genetic sequence of the chicken muscle protein from an online database in a matter of seconds, but we wanted to show people where our company’s meat will eventually come from and create a connection,” said Kelleman. “With that, we took a harmless blood sample from these happy hens to start the process.”

When Kelleman first began sharing his startup plans with family and friends, he said reactions typically skewed toward “amazing and curious served up with a side of crazy.”

Convinced of the viability of his vision, Kelleman said the ensuing challenges of “turning a napkin sketch into reality” entailed considerable financial sacrifice as he and the team experimented with their processes.

Though still in the “skinny years” of entrepreneurship, Kelleman said his company’s Plug and Play participation, both through San Francisco and Topeka’s first pilot cohort, has been a critical factor in the company’s progress.

“Fundraising isn’t easy, but Plug and Play offers beneficial workshops and facilitates networking opportunities and introductions to help us find potential partners,” he said. “The program also creates camaraderie. I can call on another startup that’s further along in the process and get insights that can help mitigate mistakes.”

The company has raised more than $2.2 million in seed funding to date with investors that include Plug and Play Ventures, Lever VC, KBW Ventures and Agronomics.

Bond Pet Foods currently has six employees who are “busting at the seams” in its Boulder lab, but “day by day, week by week, we’re getting closer to our goal,” Kelleman said.