Stevenson Company

Photos by: JOHN BURNS

Joe Pennington, president of the Stevenson Company since 2006, thinks his metal fabrication business produces the “Coolest Thing Made in Kansas.”

What is this cool product?

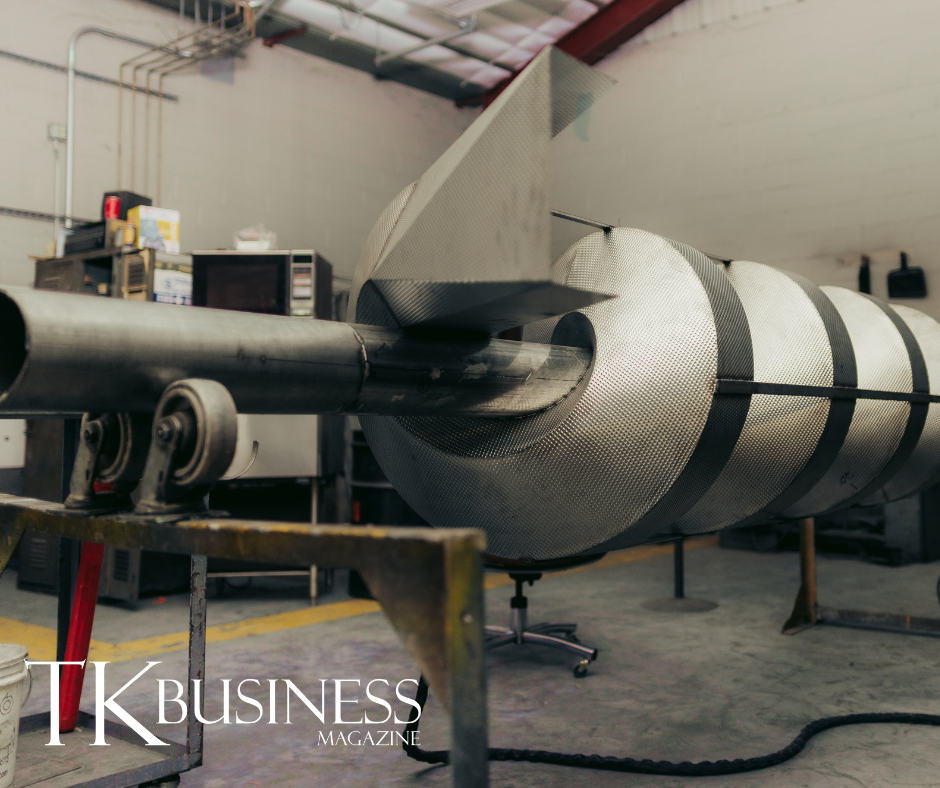

Unofficially, It’s a “slipper slide for potato chips,” as Pennington callsit. Officially, it’s a stainless-steel spiral chute used in industrial settings tosanitarily, gently and quickly move a product without that product breaking. It also is easy to clean, an efficient use of space, saves money in the long runand doesn’t require maintenance.

“If you think about a playground slide, it goes round and round and round. Except instead of little kids, it’s sized for peppermints or restaurant-style Doritos or whatever. And the slides are all custom-made. It’s very important that they start sanitary because all of them go in food plants,” Pennington said.

FINDING A NICHE

Applications for the chute include cookies, crackers, candy, chocolates, pasta, grains, pet food, pills, nuts and coffee beans.

“You know how people always say you have to find your niche in business?” Pennington said of the chutes. “Well, I found mine. It’s right between processing and packaging. It’s about 18 inches wide and 5 feet tall. That’s my niche, right there.”

While Pennington, age 53, indicated his staff and company had won innovation awards and the Topeka City of Character Award, he said his hardworking 25-employee crew could use a nod of appreciation for their work on the spiral chutes.

“I don’t know how many other companies make this type of chute, but we make them best,” Pennington said. “Ours is sanitary welded, inside and out. If you’re eating stuff off of this, you want it to be clean. That’s our hallmark for sure.”

About 90 percent of Stevenson’s fabrication work is on spiral chutes, Pennington said, and 90 percent of those ship outside the state of Kansas, with most of them in North America.

“We bring that money here, and 100% stays in Kansas. All my employees are from Kansas,” Pennington said.

HUMBLE BEGINNINGS

Stevenson Company, 116 NW Norris, has been around for several decades, dating back to the mid-20th century. The founder of the company and namesake, Mr. Stevenson, as Pennington calls him, was from Akron, Ohio (where Goodyear is from) and moved to Topeka to build the plant. Stevenson got married and stayed here, starting his own business with his first built-in customer, Goodyear. The company did industrial metal work, installing siding, gutters, roofing, platforms and ladders. And from there, industry grew in the agricultural sector and the feed market, Pennington said.

“Because we’re in the heartland and the center of agricultural activity and food processing, we grew,” Pennington said.

Pennington said his grandfather worked for Stevenson, and his father bought the company in 1990. The 1990s was also when the spiral chute came into play.

The reach for Stevenson Company goes halfway around the world to places like Malaysia, Pennington said, having shipped to five of the seven continents (no Antarctica or Africa, yet).

Regarding future prospects, Pennington is confident, saying it’s going to be hard to outsource to another country because it’s best to be in the same country or at least the same region where their slides are made.

“Because each one is specifically made, we don’t have robots that can weld them or even lay them out with a mathematical formula. Popcorn travels differently than marbles, so they’re different pitches and different widths. It’s just a really cool, great product that people need and enjoy even if they don’t think about it. You want to snap your own Oreo apart, or you want to twist it apart. You don’t want to get a broken animal cracker where you can’t even tell what animal it is. So that’s why we do it,” Pennington said.

OVERCOMING UNCERTAINTY

Pennington said one thing he’s keeping an eye on is the mining of nickel, which the company uses in its stainless-steel product. It has been going through an uncertainty recently, causing costs to shoot up. However, Stevenson Company has not faced shortages yet, but Pennington says he feels like they are coming.

“If you think people were angry about no toilet paper, wait until they run out of Doritos,” Pennington said.

Pennington serves on the board of advisors for the Kansas Manufacturing Council, which conducts the “Coolest Thing Made in Kansas” competition every year. The contest highlights the state’s manufacturing industry, which employs one out of 11 Kansas workers. The nomination period begins in August, and the winner is announced in October after ahead-to-head style tournament.